« Back

Skudo trumps slip resistance

As part of Skudo Floor’s technical objectives, the coating system was designed that not only protects the substrates below from damage and stains but also provides the highest level of safety for slip resistance in the workplace. This additional benefit allows every (coated) floor type within the site to be consistent in its tactility, thus providing a safer and lower risk work zone. This could also have advantages such as lower premiums and less downtime on site due to stoppages.

THE TEST:

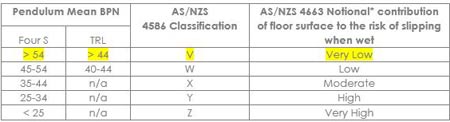

Skudo commissioned two main tests from ATTAR – a NATA Accredited facility, The Wet Pendulum Slip Resistance Test, and the Dry Floor Friction Slip Resistance Test. The wet pendulum slip resistance test (AS/NZS 4586 Appendix A) is generally conducted using a Wessex or Munro - Stanley London Pendulum Friction Tester. This pendulum device is portable and consists of a weighted foot with a test slider that swings down and slides across the surface wetted with water. The weighted foot comprises a spring-loaded rubber test slider that exerts a prescribed force over the specimen as it slides across the surface. The results of expressed as a British Pendulum Number (BPN) and classified according to AS/NZS 4586 as shown in the table below:

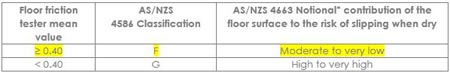

The dry floor friction slip resistance slip test (AS/NZS 4586 Appendix B) uses a battery operated machine commonly referred to as the "dry FFT" a or "Tortus". The dry FFT measures the force opposing the motion of a 9 mm diameter test slider of Four S rubber as it moves across the surfaces at a constant speed of 1m/min. The average of two measurements of 800 mm is taken and the results are expressed as Coefficient of Friction (CoF). The coefficient of friction is a ratio of the horizontal and vertical forces and the slip resistance test results are classified as follows:

THE RESULTS:

THE RESULTS:

Wet Pendulum test : mean 58 or V Classification

Dry Floor Friction test : mean 0.85 or F Classification

View PDF for full details