« Back

Skudo resisits burning

Fire performance is a requirement that is becoming increasingly important on work sites as catastrophes can occur from the smallest of incidents. Skudo is aware if this issue and developed the Skudo FR’ Floor system which combats the potential fire risks some work zones encounter by providing a fire and flame resistant temporary protective coating. To validate the performance claims, Skudo has undertaken a number of tests including flammability, heat, and smoke development.

THE TESTS:

Skudo commissioned two main tests from AWTA – a NATA Accredited facility. The first being - ASISO 9239.1-2003 Part 1. This relates to ‘reaction to fire for floorings’ and determines the burning behaviour using a radiant heat source. The test specimen is placed in a horizontal position below a gas-fired radiant panel inclined at 30° where it is exposed to a defined heat flux. A pilot flame is applied to the hotter end of the specimen. Any flame front that develops is noted and a record is made of the progression of the flame front horizontally along the length of the specimen in terms of the time it takes to spread to defined distances. If required, the smoke development during the test is recorded as the light transmission in the exhaust stack. The results are expressed in terms of flame-spread distance versus time, the critical heat flux at extinguishment and smoke density versus time.

The second test related to flammability - BS4790:1987 The test specimens are positioned in a flat circular frame and a heated (900 °C) stainless steel nut weighing 30 grams is placed on the surface and then removed after 30 seconds. The results are then recorded measuring flame extinction time, smoldering time, or time to reach outer ring. Finally the ‘radius of effects of ignition’ on both sides of the specimen which is registered as a Classification.

THE RESULTS:

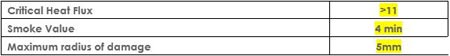

ASISO 9239.1-2003 Part 1

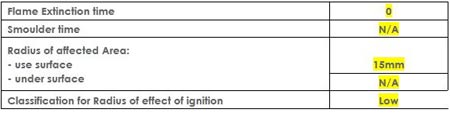

BS4790:1987

View PDF for full details

View PDF for full details